Identify Leather Types: Leather Finish

Posted by Leather Milk Customer Orders on Feb 7th 2017

UPDATE: Thanks to Barbara Carney for providing us with beautiful picture updates for aniline, semi-aniline and finished leather types. Be sure to check out her website for more great leather care info and quality repair services at www.barbsleatherservice.com!

How can I tell what kind of leather I have? How can I know the best treatment for my leather? Does all leather behave the same way, or does each kind require a different type of treatment?

These are burning questions in the hearts of leather aficionados everywhere. Today, we’re going to dispel this mystery, and get to the juicy details about how you can harness your own Sherlockian powers of observation to identify and diagnose proper leather care for your own valued leather.

This is the third of a five-part series exploring leather 101. In the first four parts, we will be exploring the different styles of leather and how it is made, assembling a catalog of various leather types. Our fifth blog will expose useful tricks to allow you to distinguish between these different types of leather, so that you can be better prepared to know your own unique leather, and know the best way to treat it. In previous blogs, we discussed how to identify types of leather cuts, and different types of tanned leather. Today, we’ll be talking about the different ways leather is finished. Following this, we will explore various kinds of animal breeds used for leather, followed by Leather Type Identification Techniques. Hope you enjoy!

Identifying Leather Finish

So you want to learn about leather finish? That is a capital idea, you! I love initiative! Leather finish represents one of the most vital attributes of your leather valuable, and will be the most noticeable thing about your leather when anyone looks at it. Whether it’s colorful and opaque, natural and organic, or somewhere in between - is a timeless question decided only by your own aesthetic tastes. Beyond this, leather finish has a defining influence about how your leather must be treated and cared for throughout its life.

But before we get too far into all this, let’s do a quick recap. If you've been keeping up, you'll know that leather develops from a tanning process, whereby hides are limed (to remove fats and other unwanted material), soaked with a variety of chemicals, and saturated with tannins which preserve the hide and prevent it from decomposing. After this, a "crusting" process begins. The hide may or may not be split or sanded down - a process whereby full grain leather is converted into top grain or genuine leather. Also during this phase, the leather's pH is controlled, the leather re-tanned, washed, and most importantly, dyed.

"Crust" Leather

These dyes, called aniline, are able to easily soak through the absorbent "crust" (tanned, un-dyed leather) and permeate your leather from front to back as the leather is saturated in large drums. Once absorbed, these dyes do not bond with the fibers that make up your leather; instead, these dyes float freely within the fiber bundles. This allows the dyes to travel, which describes what happens when you press your finger hard on a leather surface and see the space underneath lighten in color - only to turn back again as you smooth the leather out. This also means that wet leather can lose dyes, as water moves in and flushes aniline molecules out from their fiber bundles. So keep that leather protected!

Aniline Dyes

Depending on the tastes of a consumer (you!), leather may also be treated with finish - a pigmentation offering both aesthetic complement and a layer of protection against impurities. The inclusion of these pigments is what marks the great divide between finished and unfinished leather: finished leather containing these pigments, and unfinished leather lacking them. There's a spectrum between finished and unfinished leather, and much of that will be decided before your leather ever arrives in your hands. But there are ways you can change the degree to which your leather is finished, too! So what are the distinct advantages between these different types of finish, and how can I tell them apart? We are so going to answer the heck out of this question for you!

How Finish Works

Most finishing pigments are made of a blend urethanes and acrylics formed into a resin. These create, on a molecular level, very large molecules that bind to the surface of your leather, forming a solid, opaque covering over its surface. These pigments may be more or less permeable, and the film they create makes it harder for pores to absorb fluids and impurities. When leather lacks these pigments - and is therefore "unfinished" - its natural qualities are left undisguised, but so too are its pores, giving it greater vulnerability to stains, spills, and the elements.

The aesthetic difference between finished and aniline-dyed, unfinished leather is similar to, say, the difference between an unfrosted cupcake dyed with food coloring and a similar cupcake that is frosted all over. On a dyed cupcake, you can still see all of the little cake's spongy texture. But if you layer it with frosting, the frosting is all you're going to see. So it is with leather finish.

Advanced Leather Solutions have a really cool video showing different ways leather is dyed here!

When leather is being prepared, there are three primary approaches to finishing (or not finishing) it.

Aniline Leather

Aniline leather is not going to have any of that schmancy finish spoil its natural beauty. This leather comes to you as is, unclad in its naked leather glory like Michaelangelo's David in hide form. This is leather in its most natural state after being tanned and prepared. Very few full grain leathers are generally deemed worthy to be put out to market unfinished, and those that you will find tend to be more expensive. So you'll want to treat your aniline leather like the investment it is, because this thing is super absorbent, and stains quickly (happily, scratches are much easier to rub out). So giving your aniline leather sofa some protection ahead of time with Furniture Treatment No.5 is a good idea. There are a few defining characteristics you can use to identify aniline leather:

- Natural, almost coarse texture underneath the finger - may lighten in color when pressed hard, but color will return when smoothed out again.

- Possesses natural leather scents and aesthetic: grainy, with spontaneous patterns and non-uniform appearance. Marks and traits that were visible on the animal while alive are most easily seen with this leather.

- Fluids will absorb instantaneously. Scratches can usually rub out. Very breathable leather; if full grain, pores are most visible.

- More flexible and supple than finished leather, feeling slimmer without the plastic layering. Leather can display wrinkles when furled.

- Colors richer and deeper, less artificial and opaque looking. Patinas frequently and more easily. Dyes may fade under prolonged exposure to sunlight, and the leather will not shine under light unless waxed.

Semi-Aniline Leather

Semi-aniline leather is the cozy, middle path between finished and unfinished leather. Like aniline leather, semi-aniline is first saturated in dyes, but is afterward given and additional light coating of dyes and pigments at the surface. This top coat preserves the leather's most natural qualities, while giving it more protection than aniline leather and offering the dyes some resistance to fading under sunlight. Semi-aniline is the most practical choice for anyone who wants to take their leather on rough and tumble adventure while preserving its natural roots. Many Saddleback bags are prepared in semi-aniline style, made for rugged durability and exceptional utility. You can get a good idea whether your leather is semi-aniline by identifying the following characteristics:

- Mostly smooth texture, with some tactile qualities of leather's natural coarseness. Will not change color under pressure.

- Possesses slightly more muted natural leather scents and aesthetic: can be grainy, with spontaneous patterns, or may possess a slightly more uniform appearance. Marks and traits that were visible on the animal while alive can often be seen with this leather.

- Fluids will absorb more slowly. Scratches may not rub out. Fairly breathable leather, although pores will not be as easy to see.

- More flexible and supple than finished leather, but stiffer than unfinished. Wrinkles will not likely show when leather is furled.

- Color is somewhere between transparent and opaque, giving you insight into the leather's natural grain, but with a much more uniform color. May patina. Color will not be affected by UV exposure nearly as easily, and the leather will shine dimly under light.

Pigmented Leather

Pigmented leather is built to withstand. Drum-dyed like aniline and semi-aniline leather, you would not be able to tell for pigmented leather's vibrant finish. This leather has maximum protection from the elements, and requires starkly less maintenance and care when treating. This leather is made when leather is given a complete plastic coating over its surface, just permeable enough to allow the leather to breathe, but significantly slowing the absorption of any other substance, be it rain, a spilled drink, or even leather conditioner. Usually developed from leather deemed too disfigured to sell as is, you will usually find this leather sanded down to top grain and embossed to create a consistent texture. The downside to this leather is that it has abandoned many of its natural qualities, and - while it does not scratch as easily - scratches that stick are harder to get out. This finished leather is used almost ubiquitously for car leather, and is very common for furniture and upholstery. Makes sense, given the beating these types of leathers tend to put up with. If you've got leather that needs to survive some rough play, at the cost of natural quality and a somewhat smaller lifespan, this leather's for you. Pigmented leather's pretty easy to identify:

- Very smooth, almost plastic texture. Will not lighten in color under pressure.

- Will not possess many natural qualities; may smell like plastic. Uniform surface with artificial or consistent patterning. No visible grains or pores.

- Fluids will absorb much more slowly, may bead at the surface for a short time. Scratches cannot rub out. Less breathable.

- Less flexible and supple than other leathers, having a stiffer substance owing to the plastic layering. Will not wrinkle when furled.

- Colors uniform and opaque, or artificial. This leather will not patina, but will strongly resist fading under UV exposure. Shines brightly under light.

Leather may also be finished in other, less-conventional-more-stylistic ways, such as with a metallic finish, a patent finish, or by embossing. Metallic leather can usually be treated conventionally, but if you are looking to treat patent leather, I'd recommend reaching out to the manufacturer for more specific care instructions; patent's finish tends to be almost completely impermeable, making standard leather conditioners ineffective for this leather. Embossed leather is imprinted with tactile patterns, and is common for imitation exotic leathers. Embossed leather can usually be treated and conditioned like any other leather.

Your Own Finishing Touches

Your leather came to you finished or unfinished likely very long before you had a say in the matter. But that doesn't mean you can't give your leather your own finishing touches. Indeed, it's fairly simple to convert your leather from one to the other in no time at all. Finished leather, for instance, is finished to the synthetic layer sitting on its surface. Rub or sand that finish off, and your leather is unfinished again! (This is why it is important to not rub leather too hard when treating it.) If you want to make your unfinished leather into finished leather, on the other hand - or you just want to give it some extra protection - you've got plenty of options.

Oil & Wax

Oil and wax are best when you want to give your leather protection, but don't want to diminish its natural qualities. Indeed, oil and wax are very healthy for your leather, imitating the oils that nourished the leather's skin while it was still living. With time, these oils will even help your leather develop luscious patina. Wax, in particular, is handy if you want to give your leather a shiny coat. That said, these fluids can darken your leather (especially oil), so best test them first in a discreet area to ensure they are the right fit for your own, unique leather.

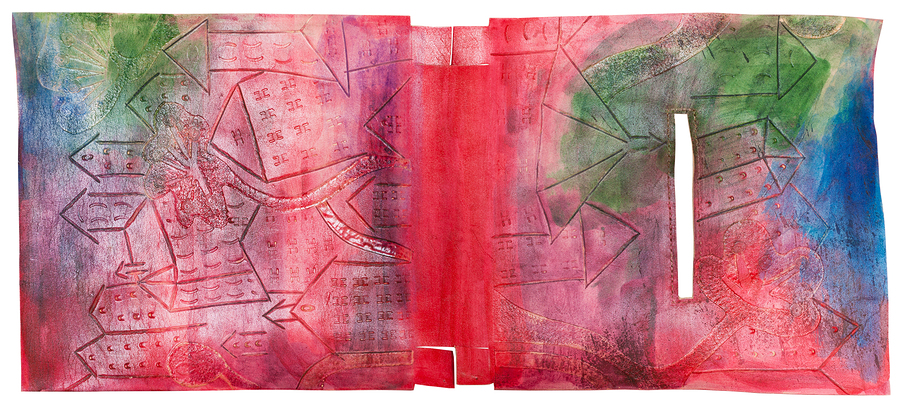

Acrylic

Dyes and paints are made from acrylic, a synthetic material, and so when applied on leather, will give it something like a standard finish. This kind of finish is very useful because it allows leather to be expressively colorful (I mean, look at that leather up there!), and works great for restoring faded color, without obstructing leather's pores so much the leather cannot breathe. In fact, it's a good idea to seal acrylic in after it has dried with a leather conditioner, to preserve the lovely finish you've just given it.

Silicone

Finally, we have silicone. This type of finish is love-hate. On the one hand, you give your leather a silicone finish, nothing is getting inside it. Silicone not only repels the elements from your leather - it completely waterproofs your leather. The downside to this is that, because your leather is waterproofed, it's not breathing at all, and that means you can't condition it, and it's going to have a drastically shorter life. This may work well for you if you need something with maximum protection but don't necessarily need it around for the long haul. In addition, the synthetic properties of this finish will give your leather many plastic-like characteristics, from scent and look to texture.

COUNT ON VARIATION

If you are still in doubt about your leather’s type after checking for these qualities in your leather, it is also a good idea to ask the leather’s manufacturer. Take note that the leather type attributes identified in this post might be enhanced or diminished by other ways the leather is prepared. For example, your chrome tanned, top grain leather may possess all the porousness natural qualities we've talked about, but beneath a coat of pigmented finish, you'd never know it was top grain! In the following posts of this series, I will discuss factors like the leather's animal breed, describing how these changes may affect your leather’s design. Don’t forget to treat your leather with Leather Care Liniment to keep it healthy and strong!

Tune in next time to learn more handy Leather Identification 101: a crash-course on leather animal types, empowering you with all the know-how you need to give your leather the love and affection it deserves.

Cheers, leather aficionados & friends!